Plastics

By application of best matching manufacturing technolgy every individual part requested from QTY 1 to large scale manufacturing can be realized:

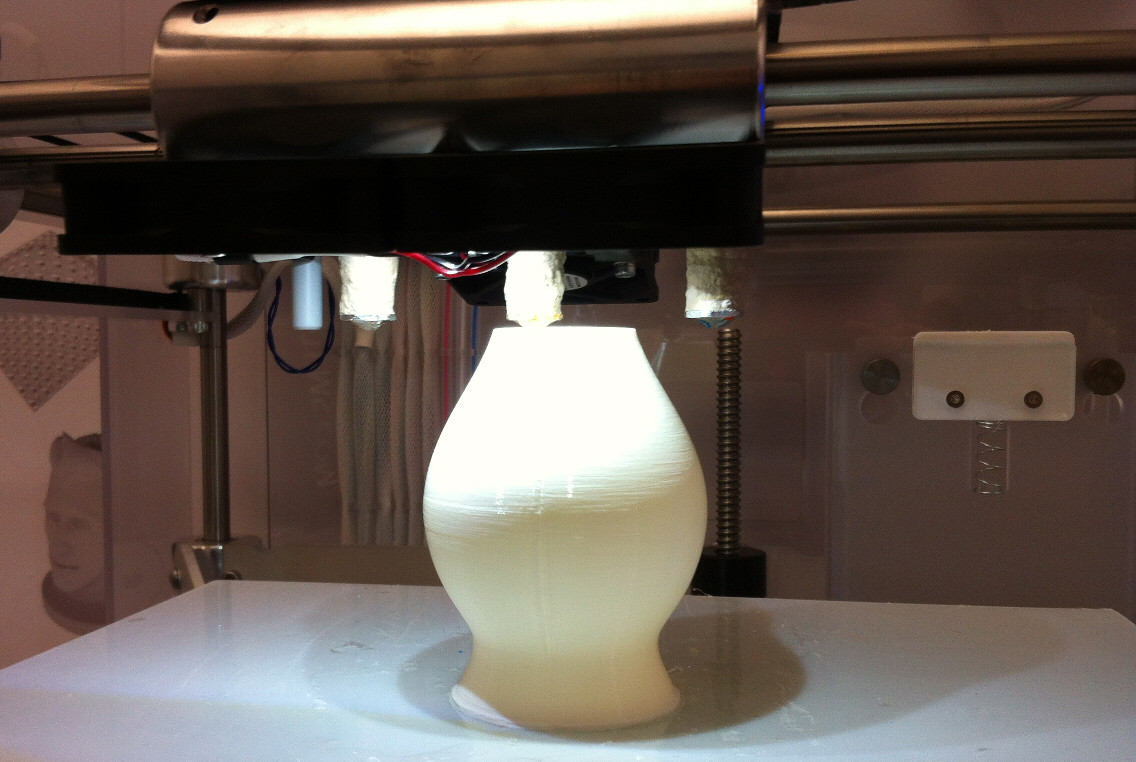

- Additive Manufacturing (FDM, "3D Printing")

- Vacuum forming

- Extrusion

- Exjection

- Injection molding

Based on experience since 1967, each spare or customization request considers a weight, material & technology analysis to optimize cost/benefit ratio. Spare parts are processed by "speed line" concept on shop-floor level.

Support services in-house are:

- Reverse engineering

- Paint shop

- Water-transfer-printing

- Pad/tampon printing

- Tooling design/manufacture

- Qualification, Burn testing acc. FAR 25.853 (a)

All used materials are qualified aerospace materials. We state a design and production approval by EASA Form 1. By established EPA (European Parts Approval) process we offer high quality spares with OEM/Tier1 standard.